Why Fashion Brands Need Production Partners

Scaling a fashion brand in the U.S. gets complicated fast. As collections grow, timelines tighten, and costs shift, production mistakes become expensive. A reliable production partner doesn’t just manufacture garments — they bring structure. From tech pack review and sampling to bulk production and quality control, the right system reduces chaos and protects your margins. This article breaks down how a structured production partner helps emerging and scaling brands move from idea to market with confidence.

Table of Contents

Key Takeaways

| Point | Details |

|---|---|

| Comprehensive Production Support | A structured production partner manages tech pack review, sampling, bulk production, and quality control, turning design concepts into consistent, scalable garments. |

| Choosing the Right Production Model | From OEM to full-package manufacturing, brands must select a system that supports their growth stage, margin goals, and level of design control. |

| Why Systems Matter for Scaling | Clear documentation, structured timelines, and factory accountability reduce costly mistakes and protect margins as brands grow. |

| Vetting Production Partners | Brands must evaluate communication structure, sampling process, QC standards, and transparency before committing to bulk orders. |

What Fashion Production Partners Actually Do

Fashion production partners do more than manufacture garments. They translate creative ideas into clear technical execution. That includes reviewing tech packs, clarifying measurements, sourcing materials, building samples, correcting fit, and preparing for bulk production with structure and oversight.

The core responsibilities of fashion production partners include:

Technical Design Translation: Converting designer sketches into precise technical specifications

Fabric Sourcing: Identifying and selecting appropriate materials that match design requirements

Sampling and Prototyping: Creating initial product samples to validate design feasibility

Fit Correction: Performing multiple rounds of sizing and fit adjustments

Cost Engineering: Developing detailed cost breakdowns and production budgets

Quality Control: Implementing rigorous inspection protocols at multiple production stages

Strong production partners prevent problems before bulk production begins. Through documentation, sampling rounds, and structured quality control, they reduce costly errors and protect timelines.

Beyond manufacturing, they provide clarity. Clear communication, defined processes, and accountability at every stage are what separate a reliable production partner from a basic factory.

Pro tip: Ask how they handle tech pack review, sampling rounds, and quality control before bulk production. If they can’t explain their process clearly, they likely don’t have one.

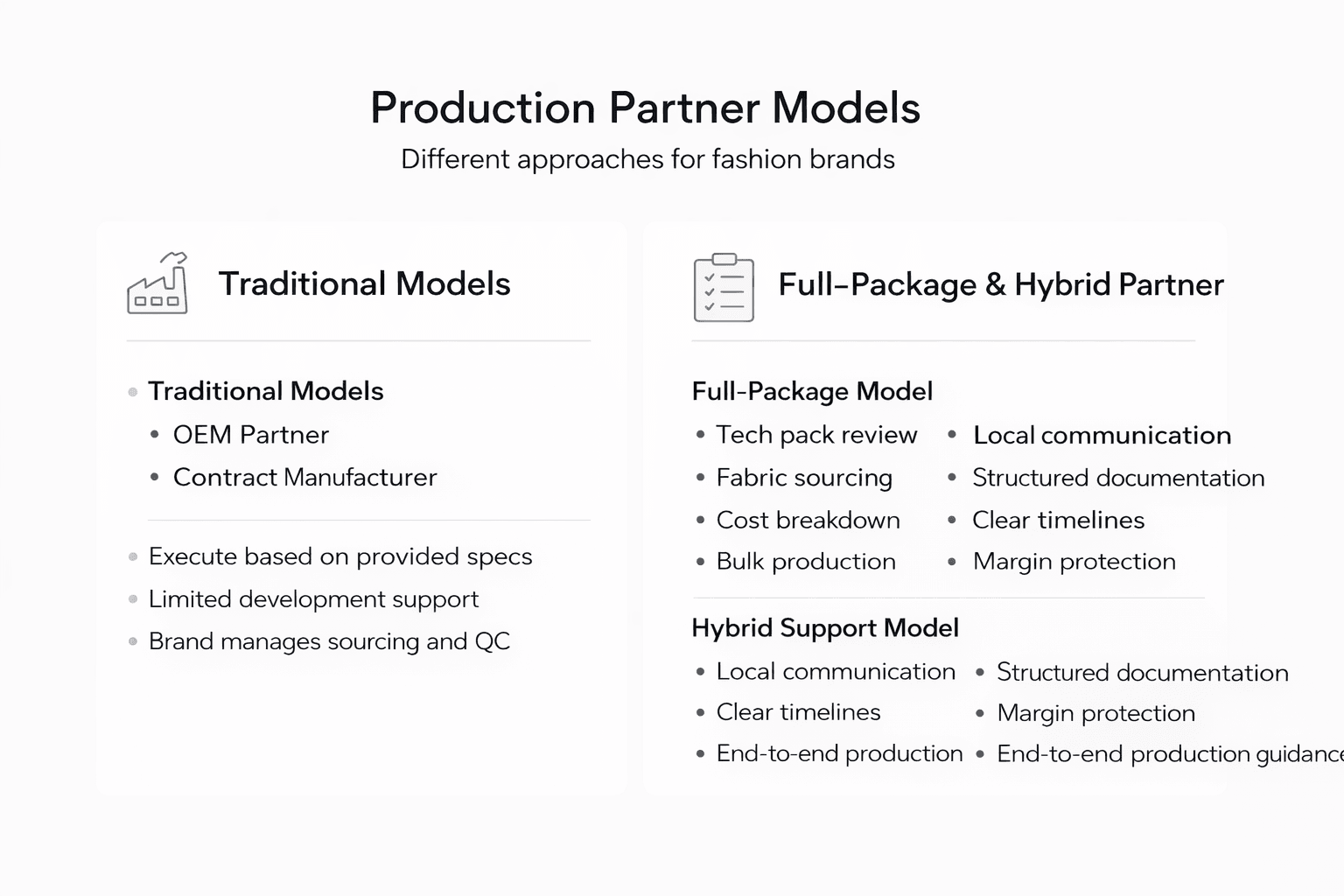

Types Of Production Partner Models

Fashion brands can work with different types of production partners depending on their stage and needs. Some factories simply execute instructions. Others offer deeper involvement in sourcing, development, and production management.

The primary production partner models include:

Original Equipment Manufacturers (OEMs): Manufacturers who build products strictly following client designs

Original Design Manufacturers (ODMs): Partners offering pre-designed products ready for brand rebranding

Contract Manufacturers (CMs): Flexible production partners handling manufacturing based on detailed client specifications

Full-Package Manufacturers: Comprehensive partners managing entire production lifecycle from design to delivery

Each model offers a different level of control and support. Early-stage designers often need more hands-on guidance, while established brands may only require structured bulk production. Choosing the right model depends on how much technical and operational support your brand needs.

Here’s how common production partner models differ on capabilities and brand impact:

| Model Type | Design Control Level | Customization Potential | Common Use Case |

|---|---|---|---|

| OEM | Full client design ownership | High flexibility in features | Brands with strong internal development teams and clear technical specs |

| ODM | Limited brand input | Quick launch with standard products | Brands looking to modify pre-developed products |

| CM | Moderate brand involvement | Adaptable to detailed specs | Brands providing detailed tech packs and managing development internally |

| Full-Package | End-to-end management | Maximum brand integration | Brands needing support with development, sourcing, sampling, and production management |

Beyond traditional models, emerging production partnerships are increasingly focused on sustainability. Innovative production models now incorporate circular economy principles, including product durability, rental and leasing systems, garment resale, and advanced recycling techniques.

Pro tip: Evaluate potential production partners not just on cost, but on their ability to align with your brand’s technical capabilities, sustainability goals, and long-term strategic vision.

Key Benefits For Growing Fashion Brands

Growing fashion brands face complex challenges that require strategic partnerships to navigate successfully. Production partners emerge as critical allies, offering comprehensive support that extends far beyond traditional manufacturing relationships. These partnerships provide a robust framework for brands to scale efficiently while maintaining high-quality standards and competitive market positioning.

Key benefits of working with production partners include:

Operational Flexibility: Ability to quickly adjust production volumes and strategies

Technical Expertise: Access to specialized manufacturing knowledge and innovative techniques

Risk Mitigation: Reduced supply chain vulnerabilities and enhanced resilience

Cost Optimization: Streamlined production processes that protect profit margins

Market Responsiveness: Faster time-to-market with adaptable manufacturing capabilities

Strategic production partnerships enable brands to navigate economic uncertainties by providing enhanced agility and support for evolving business models. These collaborations help brands respond quickly to shifting consumer priorities while maintaining high-quality production standards.

Beyond immediate operational advantages, brand value growth is significantly influenced by the quality and strategic alignment of production partnerships. Brands that invest in robust, transparent, and innovative manufacturing relationships create opportunities for premium positioning, increased consumer trust, and long-term competitive differentiation.

Pro tip: Prioritize production partners who demonstrate a commitment to continuous improvement, technological innovation, and alignment with your brand’s specific strategic objectives.

Risks Of DIY Or Unvetted Production

Attempting to manage production independently or without professional partners exposes fashion brands to significant operational and financial risks. Many emerging brands underestimate the complexity of manufacturing, assuming they can navigate production challenges through improvisation and cost-cutting measures.

The primary risks of DIY or unvetted production include:

Supply Chain Vulnerability: Increased exposure to unexpected disruptions

Quality Control Failures: Inconsistent product standards and potential reputation damage

Compliance Challenges: Higher risk of regulatory and ethical manufacturing violations

Hidden Cost Escalations: Unexpected expenses from inefficient production processes

Limited Scalability: Difficulty expanding production capacity rapidly

Production planning disruptions can create cascading challenges for small and medium enterprises, leading to financial losses and substantial operational setbacks. Without professional risk management, brands may find themselves trapped in cycles of reactive problem-solving instead of strategic growth.

Operational risks extend beyond immediate manufacturing challenges. Brands without vetted production partners face increased exposure to geopolitical uncertainties, compliance complexities, and resource access limitations. These challenges can quickly erode profit margins and compromise a brand’s market positioning.

Pro tip: Conduct comprehensive due diligence on potential production partners, including site visits, reference checks, and detailed capability assessments before committing to any manufacturing relationship.

How To Choose A Reliable Production Partner

Selecting the right production partner is a critical strategic decision that can make or break a fashion brand’s operational success. The process requires a comprehensive evaluation that goes beyond surface-level assessments, demanding a nuanced understanding of potential manufacturing relationships and their long-term implications.

Key criteria for choosing a reliable production partner include:

Industry Experience: Proven track record in your specific fashion category

Technical Capabilities: Advanced manufacturing technologies and specialized skills

Quality Control Systems: Robust testing and inspection protocols

Communication Transparency: Clear, consistent, and proactive reporting

Scalability Potential: Ability to adapt to your brand’s growth trajectory

Compliance Credentials: Verified ethical and regulatory standards

Manufacturing partner selection requires a methodical approach that begins with clearly defining your brand’s specific production needs. This includes detailed product specifications, expected volume ranges, and any specialized manufacturing requirements that are unique to your design aesthetic.

Comprehensive partnership evaluation involves multiple due diligence steps. Brands should conduct thorough background checks, request facility tours, analyze cost structures, and assess the potential partner’s reputation in the industry. Direct site visits and conversations with existing clients can provide invaluable insights into a manufacturer’s actual performance and reliability.

To help choose a reliable production partner, consider these evaluation factors:

| Criteria | Business Value | Risk Reduction |

|---|---|---|

| Industry Experience | Ensures brand-specific expertise | Minimizes unexpected setbacks |

| Technical Capabilities | Enables complex products | Enhances quality and consistency |

| Communication Transparency | Keeps information flowing | Avoids misunderstandings |

| Compliance Credentials | Builds consumer trust | Reduces legal exposure |

Pro tip: Create a detailed scorecard with weighted evaluation criteria to objectively compare potential production partners, ensuring a systematic and data-driven selection process.

Partner with Protek & Friends for Stress-Free Fashion Production

The article reveals the challenges fashion brands face when navigating complex production processes without reliable partners. From unpredictable timelines and shifting costs to communication breakdowns and quality risks, brands need more than just manufacturers—they require true production partners who provide structure, clarity, and control. If you have experienced anxiety over placing new POs or want to protect your margins while scaling effectively, Protek & Friends offers tailored solutions that go beyond traditional factory roles.

Our hybrid manufacturing model in the USA and overseas ensures operational flexibility with transparent communication throughout every step. We specialize in small to mid-size production runs and bring expertise in design review, fabric sourcing, fit correction, cost breakdown, and quality control. By implementing a structured development process, we eliminate costly mistakes and replace chaos with reliable systems.

Take control of your production journey today by partnering with Protek & Friends, where good production is designed to feel boring with zero surprises. Discover how our approach aligns perfectly with the article 2s emphasis on strategic production partnerships and clear documentation before paying to keep your brand protected.

Wondering how to shift from DIY risks to professional confidence Explore our full-package production services for growing fashion brands ready to scale safely.

Make your next collection launch a success with a partner committed to proactive communication and consistent quality. Visit https://protekandfriends.com to get started now.

Frequently Asked Questions

What are the main roles of fashion production partners?

Fashion production partners are critical allies who transform creative concepts into market-ready garments. Their main roles include technical design translation, fabric sourcing, sampling and prototyping, fit correction, cost engineering, and quality control.

How do production partner models differ in the fashion industry?

Production partner models vary in design control, customization potential, and the extent of partnership. Models include OEMs, ODMs, contract manufacturers, and full-package manufacturers, each serving different needs depending on a brand’s objectives.

What benefits do growing fashion brands gain from production partners?

Growing fashion brands benefit from operational flexibility, technical expertise, risk mitigation, cost optimization, and enhanced market responsiveness, allowing them to scale efficiently and maintain high-quality standards.

What risks does a fashion brand face if they choose DIY or unvetted production?

Choosing DIY or unvetted production exposes brands to supply chain vulnerabilities, quality control failures, compliance challenges, hidden cost escalations, and limited scalability, leading to operational setbacks and financial losses.